Applications of Activated Carbon

Our advanced Activated Carbon solutions are designed for multiple applications, delivering maximum efficiency and consistent performance to create measurable value across mining and diverse industrial operations.

Gold Recovery (In Mining)

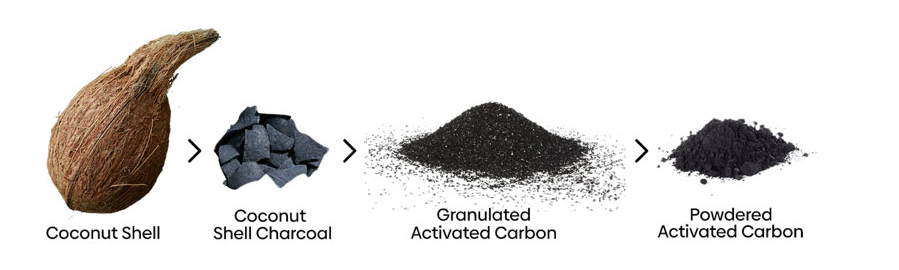

Coconut shell–based activated carbon is the Industry-Preferred Adsorbent for Gold Recovery in cyanide leaching operations. Owing to its exceptionally hard structure, high microporosity and superior adsorption kinetics, it delivers consistent and efficient recovery of dissolved gold from leach solutions.

Produced from renewable coconut shells, this grade of activated carbon offers High Mechanical Strength, Low Attrition loss and long Service life, making it ideal for repeated loading, elution, reactivation, and reuse in gold mining circuits. Its chemical stability in alkaline and cyanide environments ensures reliable performance under demanding operating conditions.

Activated carbon is used in three principal gold recovery processes, depending on ore type, grade, and operational requirements.

1. Common Gold Recovery Systems Using Activated Carbon

CIP (Carbon-in-Pulp): Carbon is added after leaching, and gold is adsorbed from the pulp.

CIL (Carbon-in-Leach): Carbon is added during leaching—adsorption and leaching happen simultaneously.

CIC (Carbon-in-Column): Used for clear solutions (like heap leach solutions) where the gold is adsorbed as it flows through carbon columns.

Carbon In Pulp (CIP)

Carbon In Pulp (CIP)

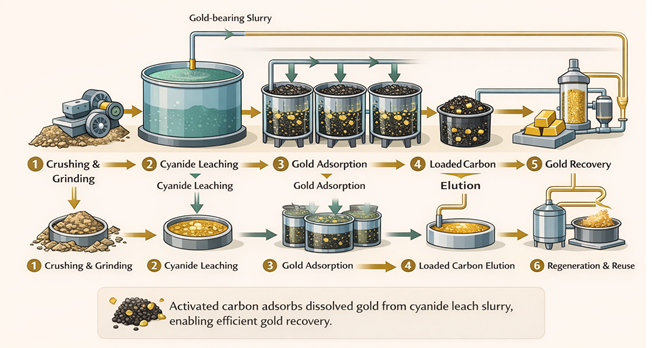

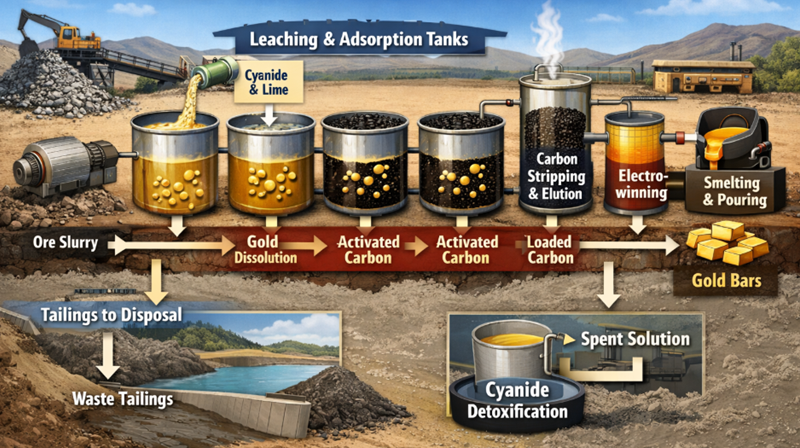

In the Carbon in Pulp (CIP) process, gold is first dissolved from the ore using a cyanide leaching solution. The resulting gold-bearing slurry is then contacted with activated carbon in a series of adsorption tanks.

Leaching and adsorption are carried out as separate process steps, allowing greater control over gold recovery. Activated carbon moves counter-current to the slurry flow, maximizing gold loading efficiency. The loaded carbon is subsequently stripped and regenerated for reuse.

Best suited for:

High-grade ores and large-scale gold processing plants requiring high recovery efficiency.

Carbon In Leach (CIL)

Carbon In Leach (CIL)

The Carbon in Leach (CIL) process combines cyanide leaching and gold adsorption in a single stage. Coconut shell–based activated carbon is added directly to the leaching tanks, where gold dissolution and adsorption occur simultaneously.

This integrated approach reduces equipment requirements, shortens processing time, and improves overall operational efficiency, especially for ores with fast leaching characteristics.

Best suited for:

Operations seeking simplified plant design, reduced capital cost and faster gold recovery.

Carbon In Column (CIC)/ Heap Leach

Carbon In Column (CIC)

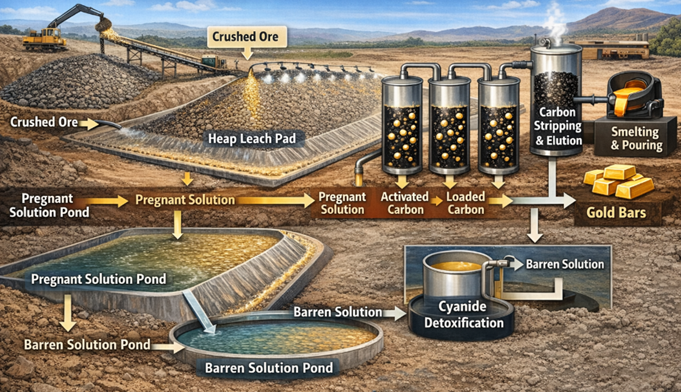

The Carbon in Column (CIC) process is widely used in heap leach operations. Crushed ore is stacked on leach pads and irrigated with cyanide solution. The gold-bearing solution collected from the heap is passed through columns filled with activated carbon, where gold is adsorbed.

Loaded carbon is periodically removed for elution and regeneration. This method is particularly effective for processing large volumes of low-grade ore.

Best suited for:

Low-grade deposits, heap leach operations, and cost-efficient large-tonnage mining projects.

1. Key Salient Features for Gold Mining Applications

- Raw Material: Made from coconut shells, a renewable and sustainable resource.

- Micro porosity: High proportion of micropores (pores <2 nm), suitable for trapping small molecules like gases and volatile organic compounds.

- Hardness: High mechanical strength, meaning it does not easily break during handling or use.

- Low Ash Content: Less impurity, better efficiency in filtration and chemical reactions.

- Surface Area: Typically between 900–1200 m²/g, depending on the activation process.

2. Production Process of Activated Carbon for Gold Mining Applications

- Carbonization: Coconut shells are heated in the absence of air to form char.

- Activation: Char is treated with steam or chemicals (e.g., phosphoric acid, potassium hydroxide) at high temperatures (600–900°C) to develop its porous structure.

ACTIVATED CARBON FOR WATER PURIFICATION

Water Purification

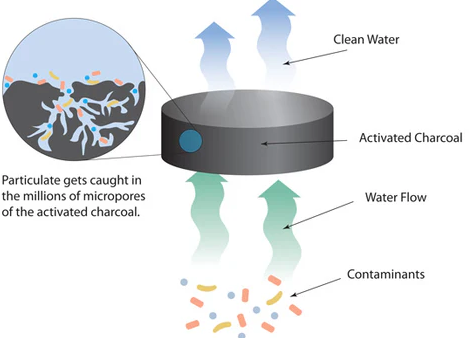

Activated carbon plays a critical role in the water purification industry due to its exceptional adsorption capacity and highly porous structure. Activated carbon works primarily through a process called adsorption, where impurities present in water adhere to the extensive internal surface area of the carbon. Unlike absorption, adsorption occurs on the surface of the carbon’s microscopic pores, which trap contaminants effectively. It is widely used to remove organic contaminants, chlorine, odors, color, and toxic substances from water, making it safe for industrial, municipal, and potable use. Activated carbon is an essential and proven solution in the water purification industry. Its superior adsorption capability, versatility, and reliability make it a preferred choice for producing clean, safe, and high-quality water across multiple industries.

Activated Carbon is widely used in

Activated Carbon widely used in

- Drinking water treatment plants

- Industrial process water purification

- Wastewater treatment

- Bottled water production

- Desalination pre- and post-treatment

- Food & beverage industry water systems

ACTIVATED CARBON FOR GAS PURIFICATION

Gas Purification

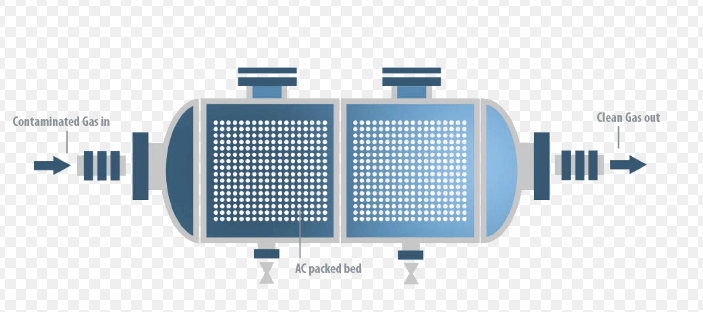

Activated Carbon plays a vital role in gas purification and air treatment by effectively removing harmful contaminants, odors, and volatile compounds from gas streams. Its highly porous structure and large internal surface area allow it to adsorb a wide range of gaseous pollutants, ensuring cleaner, safer, and regulatory-compliant operations across industries.

Activated carbon is widely used in Industrial exhaust treatment, chemical processing, oil & gas, food processing, pharmaceuticals, wastewater treatment plants, and indoor air purification systems. Activated carbon offers a cost-effective, efficient, and versatile solution for gas purification across diverse industries. With proper grade selection and system design, it ensures cleaner air, safer operations, and reduced environmental impact.

Applications of Activated Carbon in Gas Purification

Used in Gas Purification

Industrial Emission Control: Activated carbon filters are used to treat exhaust gases from chemical plants, refineries, paint booths, and manufacturing units, helping industries meet environmental emission standards.

Oil & Gas and Petrochemical Industry: Used for removal of sulfur compounds, hydrocarbons, and toxic gases from process streams and vent gases.

Indoor Air and HVAC Systems: Activated carbon filters improve indoor air quality by removing odors, VOCs, and harmful airborne chemicals in commercial and residential buildings.

Safety and Personal Protection: Used in gas masks and respirators to protect personnel from toxic and hazardous gases.

ACTIVATED CARBON FOR AIR PURIFICATION

Air Purification

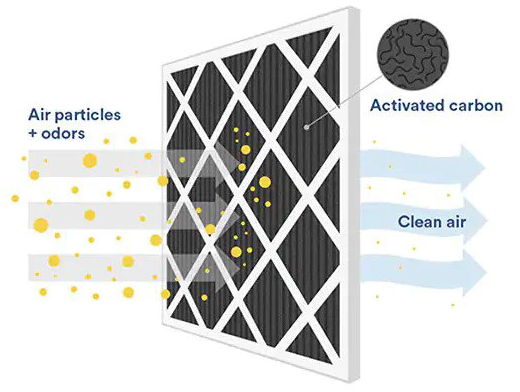

Activated carbon is widely used in air purification systems due to its exceptional ability to adsorb odors, volatile organic compounds (VOCs) and harmful gases from indoor and industrial air streams. Its highly porous structure provides a large surface area, enabling effective capture of contaminants and improving air quality in homes, offices, factories, and chemical plants.

Activated carbon is capable of removing:

- Odors from cooking, smoke, chemicals, and industrial processes.

- Volatile Organic Compounds (VOCs).

- Formaldehyde and other harmful indoor gases.

- Hydrogen sulfide (H₂S), ammonia (NH₃), and sulfur dioxide (SO₂).

- Industrial chemical fumes and solvent vapors.

- Harmful emissions from manufacturing or laboratories.