Activated Carbon

Activated Carbon is a porous material that removes organic compounds, pollutants, contaminants and other impurities from liquids, gases, chemicals, metals, etc. Our diverse Product Portfolio ranges from Acid Washed Grade Activated Carbon, Unwashed Grade Activated Carbon, Granular Activated Carbon (GAC) to Powdered Grades of Activated Carbon (PAC). Different sizes are defined for different applications. Activated Carbons have many different uses, from filtration to purification and beyond.

The Carbon-in-Pulp (CIP) and Carbon-in-Leach (CIL) methods are widely adopted processes for extracting gold from cyanide leach solutions. Activated Carbon plays a vital role in adsorbing dissolved gold ions, enabling high recovery rates and efficient purification. Our premium Coconut-Shell Based Activated Carbon is specially designed for gold cyanidation circuits (CIP/CIL/CIC). The product ensures superior adsorption performance, mechanical strength and longevity.

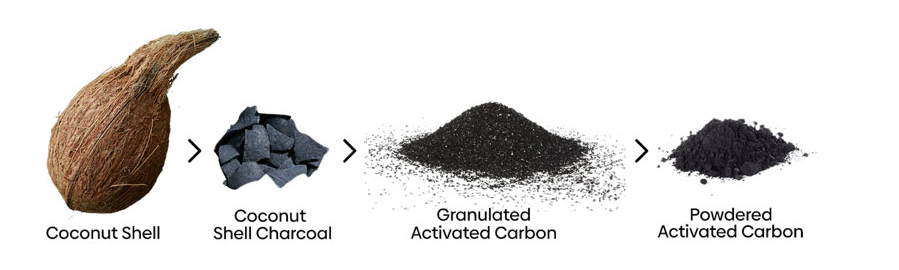

Activated carbon can be made from various raw materials which affect its pore structure and adsorption capacity and categorisation is based on raw materials such as Coconut Shell Based Activated Carbon, Wood Based Activated Carbon & Coal Based Activated Carbon.

The largest gold mining operations use coconut shell activated carbon and this is the best industry standard recommendation, so we are using this Coconut shell based Activated Carbon for manufacturing. Activated carbon purifies our world not apparently. It makes water drinkable; the air breathable and food stuffs edible. It ensures we have the best healthcare, and that we can enjoy the freedom, and technological advances of the modern world.

Types of Activated Carbon

ACTIVATED CARBON FOR GOLD MINING APPLICATIONS

- Common Gold Recovery Systems Using Activated Carbon

CIP (Carbon-in-Pulp): Carbon is added after leaching, and gold is adsorbed from the pulp.

CIL (Carbon-in-Leach): Carbon is added during leaching—adsorption and leaching happen simultaneously.

CIC (Carbon-in-Column): Used for clear solutions (like heap leach solutions) where the gold is adsorbed as it flows through carbon columns. - Key Salient Features for Gold Mining Applications:

Raw Material: Made from coconut shells, a renewable and sustainable resource.

Micro porosity: High proportion of micropores (pores <2 nm), suitable for trapping small molecules like gases and volatile organic compounds.

Hardness: High mechanical strength, meaning it does not easily break during handling or use.

Low Ash Content: Less impurity, better efficiency in filtration and chemical reactions.

Surface Area: Typically, between 900–1200 m²/g, depending on the activation process.

- Production Process of Activated Carbon for Gold Mining Applications

Carbonization: Coconut shells are heated in the absence of air to form char.

Activation: Char is treated with steam or chemicals (e.g., phosphoric acid, potassium hydroxide) at high temperatures (600–900°C) to develop its porous structure.

Why Activated Carbon Works for Gold Adsorption

- Highly Porous Structure:

Activated carbon has an extremely high surface area (500–1500 m²/g).

The internal pores provide sites for the gold-cyanide complex to adsorb.

- Hydrophobic Interactions:

Gold-cyanide complexes are slightly hydrophobic.

Activated carbon is also hydrophobic, so the complexes are attracted to and retained on the carbon surface.

- Van der Waals and Electrostatic Forces:

Weak forces help hold the gold complexes on the carbon.

In CIP/CIL systems, the carbon is kept in contact with the slurry for enough time for maximum adsorption.

- Selective Affinity:

Activated carbon shows a higher affinity for [Au(CN)_2]^ − compared to many other metal cyanide complexes, making it selective and efficient for gold recovery.

What Happens After Adsorption?

- Elution:

The gold is stripped from the carbon using a hot caustic solution.

This produces a concentrated gold-bearing solution.

- Electro winning or Precipitation:

Gold is recovered from the solution via electro winning or chemical precipitation.

- Carbon Regeneration:

The stripped carbon is thermally regenerated (often in a kiln) to remove any residual organics or contaminants, restoring its adsorption capacity.